Product Info

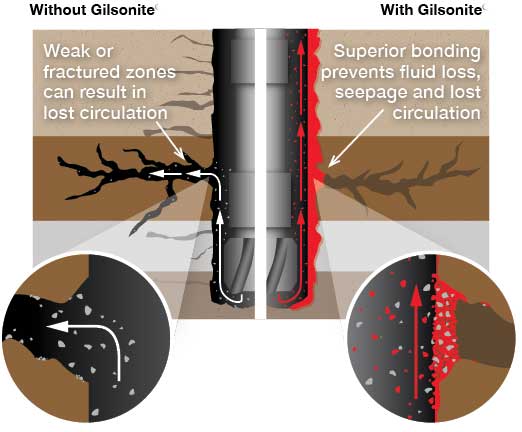

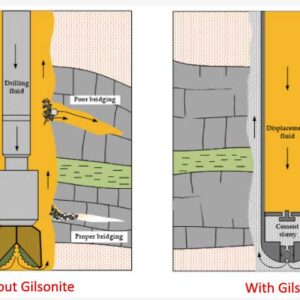

Gilsonite will prevent form tissue damage to the wall of the well if we wanted to explain the Gilsonite will make a chemical and physical bond with the permeable materials in the drilling fluid process and will make a seal for preventing the oil well contents from going out of the oil well wall or from outside the well any material leakage to the well. With this unique function, Gilsonite controls fluid leakage and leakage and protects well surfaces even at low temperatures.

Gilsonite strengthens the wellbore so By adding Gilsonite to drilling fluids, it will strengthen the oil well wall in high-pressure areas by acting as below:

- sealing micro-fractures and porosity sands

- Reducing pore pressure transmission

- Keeps the formations between the beds intact

- Creates an excellent filter cake

- As a very strong sealant, it constantly protects the oil well wall

GILSONITE WILL PREVENT FROM TUBE CLOGGING

In Drilling fluid operation it would be very important to prevent from Tube and differential clogging so Gilsonite by complete sealing of permeable formations even in areas with very high-pressure differences and improving filter cake lubrication will minimize the occurrence of clogged pipes and tools

ADVANTAGE OF USING GILSONITE IN DRILLING FLUIDS

Gilsonite, due to its natural nature, has many health benefits for the seas and the environment because it is not non-toxic Like coal and fly ash and it is not carcinogenic and mutagenic too and it is safe for use and storage and has environmental safety tips for use in Gulfs and deep waters.

GILSONITE ADDITIVE IS VERY ECONOMICAL IN DRILLING FLUIDS

If we compare Gilsonite with alternative products, its efficiency is much higher and more effective at a much lower cost, and compared to other common drilling additives, the cost of using Gilsonite is between 25% and 50% less than others.

GILSONITE FOR DRILLING FLUIDS SPECIFICATION

| SPECIFICATION | TEST METHOD | A.S.T.M |

| Ash content | 5-7% | D3174-4 |

| Solubility in CS2 | 81 | D2042 |

| Fixed Carbon | 24 | D3172 |

| Hydrogen Content | 6.5 | Elemental Analyzer |

| Sulfur Content | 0.3 | Elemental Analyzer |

| Carbon | 82 | Elemental Analyzer |

| Moisture Content | 1% | D3174 |

| Penetration | 0 | D5 |

| Specific gravity @ 25 C° | 1.2 | D3172 |

| Softening Point | 250-260 | E28-92 |

Reviews